When baking, food-making, or candy-making, adding flavoring to your meal is of utmost importance. No matter the diet of anyone, producers understand that flavoring for healthy snacks tastes good and better. Emulsion in flavoring makes it taste purer because of its water-based elements. Also, it helps flavor blend into food items, unlike flavor extract.

Flavor Emulsions: How it’s Different from Food Flavoring Extracts

Flavor emulsions and food flavoring extracts are flavor ingredients used for baking, cooking, etc. The difference is that the latter are flavorings that are soluble in a base of alcohol. Also, emulsions are usually thicker than extract and are generally opaque or cloudy. That is why extracts are preferred in beverages. Types/categories of food grade flavoring include;

- Artificial flavors

- Spices

- Natural flavors

Their uses also differ in baking and cooking in that flavoring emulsions do not “bake out,” retaining their flavor integrity in food. While flavoring extract helps flavor last longer in nutrition with a powerful aroma because of its alcohol base.

Emulsion in flavoring

Flavor emulsions are concentrated water-soluble flavorings suspended in a base majorly made of water. Flavoring emulsions are resistant to high heat, making them a perfect ingredient for food cooking and baking.

In an emulsion, the flavors are suspended in a base containing water and vegetable gum, having a thick consistency that mixes well during baking. Emulsion flavors do not contain alcohol but are more of water concentrate. This makes them great for pudding, custards, frosting, etc.

Food Flavor Extract VS Emulsion: What is the Difference Between Extract and Flavor Emulsion

Bakery Emulsion vs. Extract

Bakery emulsions are flavors suspended in a mixture of water and vegetable gum and, as such, can withstand high heat during baking without evaporating and losing their essential oil. In contrast, bakery extracts are suspended in alcohol which evaporates faster, taking some flavor and smell with it.

Strawberry Emulsion vs. Extract

Strawberry emulsions are excellent for baking because of their thick syrup texture that gives batters and doughs consistency while retaining their flavor, aroma, and color on high heat. Also, it’s perfect for flavoring, coloring cakes, frosting, etc. On the other hand, strawberry extracts are suitable for cake baking, bread, etc. but shouldn’t be used for chocolate because of their alcohol content, which can cause the strawberry to seize.

Vanilla Emulsion vs. Extract

Vanilla emulsions are vanilla flavors suspended in water and vegetable gum, while vanilla extracts are natural extracts from vanilla pods using alcohol. Vanilla emulsions are from artificial ingredients and additives, while extracts are from natural sources.

Almond Emulsion vs. Almond Extract

Almond emulsion is a potent flavoring ingredient containing bitter almond oil suspended in a mixture of water and propylene glycol. In contrast, pure almond extract is made with water, bitter almond oil, and alcohol.

Flavor Emulsion Process

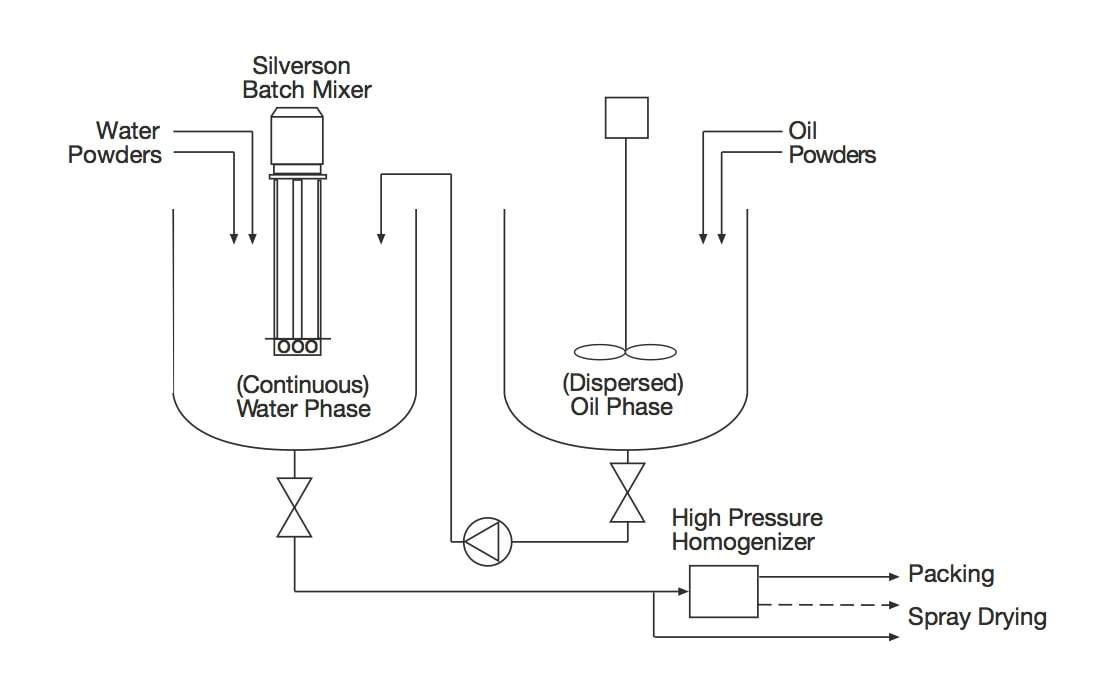

Image Source: Silverson.com

The diagram above explains how emulsions are formed. Typically, a flavor emulsion contains essential oils, water, emulsifiers, and stabilizers (e.g., Arabic gum). A high-shear mixing machine is always involved in the emulsion process. Explaining the diagram above, the process goes thus;

- The continuous phase is pumped into the mixing vessel, while the powdered ingredients are added to the phase without mixing.

- The rotor rotates at high speed to create a powerful suction, drawing liquid and solid substances into the workhead, where intense shear occurs.

- The powdered ingredients are de-agglomerated, forcing the product out through the stator at high speed and returning to the mix. At this stage, fresh ingredients are also drawn back into the workhead.

- The intake and expulsion of the ingredients create a circulatory pattern within the vessel.

- After a while, the ingredients pass through the workhead (where emulsification occurs), and dispersion is completed.

How to Make Flavor Emulsion: Manufacturing of Emulsion

Emulsion manufacturing is crucial in drinks, food, sauces, beverages, etc. All emulsions consist of thickeners, essential oils, gums, and stabilizers that must be wetted together, hydrated, and de-agglomerated, requiring different phases. To prepare flavor emulsion, you need a high shear-mixing process. The step-by-step process includes;

- Step 1: Water Phase and Oil Phase:

-

-

- Dissolve the right amount of preservatives, coloring, citric acid, and gum. Starting with the preservatives and ending with the gum to ensure a proper mixture.

- Dissolve the weighted agent in the oil and the right proportion.

-

-

- Step 2: Pre-homogenisation

-

-

- Mix water with the oil to create a premix, breaking the oil into tiny droplets.

-

-

- Step 3: Homogenization

-

-

- The premix created in step 2 is passed through the homogenizer’s valve at high pressure. This step further breaks the oil droplets into fine particles.

-

-

Flavor Emulsion Technology

Flavor emulsion technology is a colloidal system involving two immiscible liquids (oil and water) that are made to completely emulsify in the presence of an emulsifier by applying energy/high heat input. The process is essential to reach stability. If you need further clarity on this, ginhong is a Chinese-based industrial mixer and blender manufacturer, and we’re ready to help you through.

Equipment for Emulsification

The equipment for emulsification is listed below;

1. RS Vacuum Emulsifying Mixer

Image Source: Ginhong.com

Vacuum emulsifying mixers are suitable for producing small to medium-sized batches of flavor emulsion.

2. Open Storage Tank

Image Source: Ginhong

Storage tanks hold liquids, solids, and semi-solids, keeping products or suspensions in flavor emulsion evenly mixed in a mixing system.

3. High Shear Mixer

Image Source: Ginhong website

The high shear mixer is a powder induction system for mixing and dispersing powder in liquid in the food, chemical, and pharmaceutical industries. In flavor emulsion, it helps in homogenizing all suspensions together.