Engage, inspire, and know the proper blender —discover the intricacies of how lipstick is made that marries vibrant art with precise science.

Key Takeaways:

- Unravel the process behind the beloved beauty staple that graces cosmetic bags worldwide.

- Demystify the ingredients list—separating fact from fiction regarding what goes into a tube of lipstick.

- Learn actionable tips to prolong the wear of your lipstick and master the matte look.

The Essential Components of Lipstick

Lipstick has painted smiles and boosted confidence for centuries, evolving from natural stains to the modern stick form we know and love. But have you ever pondered over the concoction that makes up a single tube of lipstick? It’s a blend of science and aesthetics, with each ingredient playing a pivotal role.

The base of any lipstick lies in its trio of waxes, oils, and pigments. Waxes such as beeswax and carnauba wax lend structure and texture, while oils like castor oil and shea butter bring in hydrating properties, ensuring the lipstick glides on your lips.

Pigments give lipstick its color—these are finely ground powders that can come from a variety of sources, reflecting every shade imaginable.

The Whale Fat Controversy in Lipstick Production

Another common myth is that lipstick contains whale fat, which refers to an ingredient called spermaceti from the sperm whale. Due to conservation efforts and cruelty-free practices, this ingredient is no longer a staple in the industry.

Today, plant-based oils and synthetic substitutes offer the same qualities without harming marine life, reflecting the industry’s shift toward sustainability and animal welfare.

The Manufacturing Process of Lipstick

From melting and mixing to molding and packaging, the creation of lipstick is a meticulous process.

Initially, the base waxes are melted down, followed by the gradual addition of oils and pigments. This mixture is then stirred continuously to ensure even color distribution and a smooth texture.

Once the base is perfected, it’s poured into molds to set into the familiar bullet shape.

The final step is the application of the product into the tube—a process that combines precision engineering with a touch of elegance.

Let’s take a closer look at each step.

1. Melting and Mixing: Crafting the Base

The journey begins in the heart of the lipstick cosmetic factory, where large vats are used to carefully melt the base waxes and oils. The consistency of the temperature is key here—too hot, and the mixture could burn, too cool, and it won’t combine properly. Once these primary ingredients have melted into a homogenous liquid, it’s time for the colors to make their entrance.

2. Pigmentation: The Color of Beauty

Pigments are introduced to the liquid base in a process that requires a meticulous eye for color and precision. This is where the art of color theory meets the precision of the manufacturing. The pigments, often a combination of various shades, are slowly blended to achieve the perfect hue. This mixture is then vigorously stirred, ensuring an even distribution of color, so every lipstick bullet is uniform.

3. Molding: Shaping the Iconic Bullet

As the molten lipstick starts to take shape, it is carefully poured into molds. These molds are the negative space of the iconic lipstick bullet, and they must be crafted with exactness to ensure a smooth, flawless finish.

The mixture is then cooled—rapidly, yet carefully—to solidify the shape. The rate of cooling is crucial; too fast, and the lipstick may crack, too slow, and it could sweat or become too soft.

4. Flaming: Achieving the Perfect Finish

Once the lipstick has set, it’s not quite ready for its debut. The bullets are carefully removed from their molds and passed through a flame. This process, known as flaming, melts the outermost layer of the lipstick ever so slightly, creating a smooth, flawless finish that adds a touch of shine and ensures the stick glides over your lips with ease.

5. Inspection: The Quality Promise

Quality control is a vital part of the process. Each bullet is meticulously inspected for imperfections. A lipstick that doesn’t meet the rigorous standards is recycled back into the batch, ensuring nothing goes to waste.

6. Filling and Casing: The Final Touches

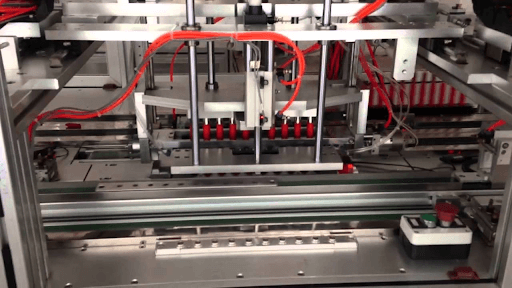

The final stage is as automated as it is enchanting. The bottom of the lipstick tube, often referred to as the base, is ready to receive its precious cargo. The filled bases are then paired with the freshly made lipstick bullets. A precise machine gently presses the two together, and voilà, the lipstick is nearly ready for you.

7. Packaging: Ready for the Spotlight

The final product is then carefully encased in its packaging, which not only protects the lipstick but also serves as a canvas for the brand’s identity. The packaging process is a blend of automated machinery and human touch, ensuring that each lipstick is presented at its best.

8. Ensuring Lipstick Longevity

You invest in a lipstick for its color and feel, but also for its staying power. Nothing is more frustrating than a lipstick that disappears after the first sip of coffee. So, how do you make lipstick last longer?

Ethical and Sustainable Practices in Lipstick Production

In the wake of environmental and ethical consciousness, the beauty industry is undergoing a green revolution.

The Greening of Lipstick Manufacturing

The sustainability of your lipstick extends beyond its ingredients. Manufacturers are adopting greener practices, from sourcing sustainable palm oil to utilizing renewable energy in production. The packaging is also getting an eco-friendly makeover with recyclable materials and refillable options becoming increasingly popular.

Cruelty-Free and Vegan Lipsticks

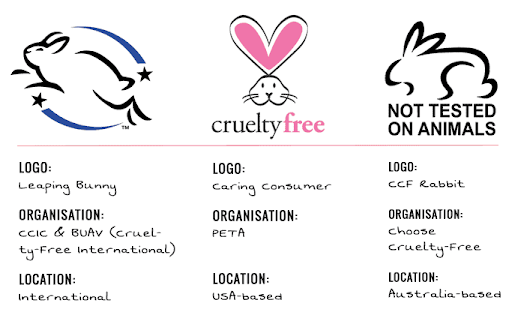

Cruelty-free and vegan cosmetics are no longer niche; they’re a growing expectation among consumers. Brands are taking note, formulating lipsticks without animal testing or animal-derived ingredients. Look for certifications from organizations like Leaping Bunny or PETA as a mark of cruelty-free products.

Innovative Formulations and Future Trends

The beauty industry never stands still, and lipstick is no exception. From the labs to your lips, here’s a sneak peek into the future of lipstick.

The Science of Color: Next-Generation Pigments

Emerging technologies in pigmentation allow for brighter, purer colors without relying on heavy metals or synthetic dyes. Expect to see lipsticks with clearer, more vibrant hues that also boast skin benefits.

Texture and Treatment: Lipstick with Benefits

The future of lipstick lies in its ability to do more than just color. Lipsticks that offer hydrating, plumping, and anti-aging benefits are on the rise, blurring the lines between makeup and skincare.

FAQs About Lipstick

Are lipsticks made of fish skin or whale fat?

No, modern lipsticks are not made of fish skin or whale fat. The beauty industry has largely moved away from using animal-derived ingredients like fish scales and spermaceti, shifting towards synthetic and plant-based alternatives that are ethically sourced and vegan-friendly.

Is animal fat still used in lipstick production?

While historically some lipsticks were made using animal fat, many brands today opt for plant-derived oils and butter. This shift is driven by ethical concerns and the demand for cruelty-free products, leading to superior hydration and smoother textures without using animal fat.

What ingredients ensure the smooth application of lipstick?

Ingredients like castor oil, shea butter, and various plant-derived oils and butter ensure that lipstick glides smoothly on your lips. They provide hydration and give lipstick its creamy texture, making application effortless.

How can I make my lipstick last longer?

To make your lipstick last longer, start by exfoliating your lips to create a smooth base. Apply a hydrating lip balm, followed by a lip primer or foundation to help the lipstick adhere better. Outline and fill in your lips with a lip liner before applying your lipstick. After applying, blot with a tissue and add a second coat for longevity.

Can I make any lipstick matte?

Yes, you can transform a glossy lipstick into a matte finish. After applying your lipstick, cover your lips with a thin tissue and lightly dust translucent powder over the tissue. This will give your lipstick a matte appearance without altering the original color.

Conclusion

From its composition to its manufacturing and its impact on the world, lipstick represents the blending of beauty, science, and social consciousness. The precision with which lipstick is manufactured owes much to the specialized equipment used in the process.

Ginhong’s state-of-the-art mixers are designed to seamlessly blend the waxes, oils, and pigments that form the backbone of a lipstick’s formula.

Our firsthand experience in the technological advancements and meticulous engineering goes into our industrial machinery. Our collaboration with cosmetic manufacturers and other lipstick equipment manufacturers is what makes our industrial mixers best at the mass production and even small-batch production of uniform and high-quality lipsticks. Contact us for a quote now!