Have you ever wondered, “How is xanthan gum made?” Which industrial mixer should be used to manufacture xanthan gum? Find out here!

Xantham gum is a versatile substance, found in everything from your favorite salad dressing to toothpaste, and starts its journey in a quite fascinating way. Xanthan gum is a hero in the culinary and pharmaceutical worlds, but its creation is a tale of science and innovation.

Key Takeaways:

- Xanthan Gum Production: It’s made by fermenting sugars with Xanthomonas campestris bacteria.

- Specialized Equipment: Essential tools include fermentation tanks, centrifuges, drying systems, high-shear mixers, and advanced mixers for dispersion.

- Versatility: Used extensively in food, pharmaceuticals, and other industries for thickening and stabilizing.

- Global Safety and Versatility: Meets international safety standards and suits various dietary needs like vegan, halal, and kosher.

- Ginhong Mixers: Advanced mixing technology for complete solid dispersion in high-viscosity applications.

What is Xanthan Gum Made Of?

At its core, xanthan gum is a polysaccharide. This means it’s essentially a sugar-like carbohydrate. The key player in its production is a microbe called Xanthomonas campestris. This little bacterium is the star that transforms simple sugars into something remarkably useful.

Application of Xanthan Gum in the Food Industry

Why is xanthan gum used in food? Its superpower is its ability to stabilize and thicken, making it a must-have in many recipes. And it’s efficient – a little goes a long way, with usually no more than 0.3% of xanthan gum used in food products.

Xanthan gum’s thickening and stabilizing properties also make it invaluable in products ranging from food to pharmaceuticals.

Ginhong’s mixers are tailored to meet the diverse requirements of these industries, ensuring high-quality results.

Global Safety and Dietary Standards

One of the great things about xanthan gum is its global acceptance. It’s not just safe according to the U.S. Food and Drug Administration, but also approved worldwide. Plus, it fits into various dietary needs – whether you’re vegan, keep halal, or follow kosher dietary laws, xanthan gum is an ally in your kitchen.

The Core Manufacturing Process

How is xanthan gum made? It’s all about fermentation, a process not unlike what happens in bread-making or brewing beer. In the case of xanthan gum, specific sugars are mixed with our microbial hero, Xanthomonas campestris. The bacteria eat the sugars and, in turn, produce xanthan gum. It’s science and nature working together!

Here’s the detailed manufacturing process:

Fermentation

The journey begins with the fermentation of sugars like glucose or sucrose. Xanthomonas campestris bacteria are introduced into a nutrient-rich fermentation medium, which they consume, producing xanthan gum as a byproduct.

Monitoring

Throughout this process, conditions such as pH, temperature, and nutrient levels are meticulously monitored to optimize yield and quality.

Harvesting

Once fermentation is complete, the mixture contains xanthan gum, bacterial cells, and residual nutrients. The next step is to separate the gum from this mixture.

Advanced Mixing and Hydration Techniques

- Dispersion in Water: For industrial mixing, proper dispersion of xanthan gum in water is crucial. The temperature impacts its solubility, but the focus is on optimizing mixing efficiency.

- Preventing Lump Formation: Gradually adding xanthan gum powder into a vortex and continuing mixing for hydration prevents lumps. Other methods include mixing with sugars or powders to reduce agglomeration and using oils for pre-dispersion.

Key Xanthan Gum Manufacturing Equipment

When diving into the manufacturing process, it’s essential to know the tools of the trade. The journey of xanthan gum from a bacterial byproduct to a kitchen staple involves several key pieces of equipment:

- Fermentation Tanks: Here, the bacteria and sugars meet and the fermentation magic happens.

- Centrifuges: These are used to separate the newly formed xanthan gum from the rest of the fermentation broth.

- Drying Systems: After separation, the xanthan gum is dried out to form the powder we commonly use.

- Milling Equipment: Finally, the dried gum is ground into the fine powder that can easily blend into your recipes.

Ginhong Mixer Technology for Industrial Applications

- Planetary and Multi-Shaft Mixers: Ideal for high-viscosity ingredients, these mixers ensure thorough mixing and dissolution.

- Dual Mixing Movements: Ginhong’s Planetary Mixers combine high-speed vertical axis rotation with slower rotational movement around the bowl center, ensuring complete ingredient integration.

- Heat-Assisted Dissolving: The jacketed design aids in dissolving additives, binders, and adhesives, creating a uniform solution devoid of voids.

Environmental and Sustainability Aspects

If you’re concerned about the environment, here’s some good news: xanthan gum production is pretty sustainable. The process is efficient and controlled, minimizing the environmental footprint.

Addressing Myths: Animal Derivatives in Xanthan Gum

A common question is, “Is xanthan gum made from animals?” The answer is a resounding no. It’s completely vegan-friendly, making it a go-to option for various lifestyles and dietary preferences.

Industrial Versatility of Xanthan Gum

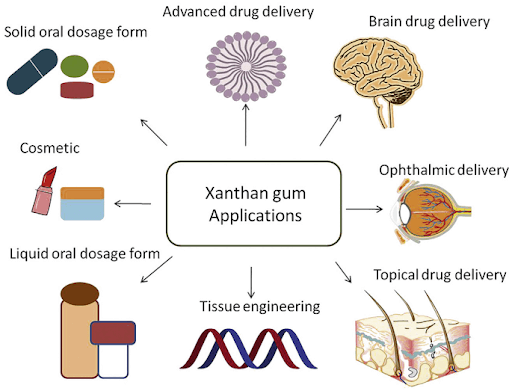

Beyond your kitchen, xanthan gum plays a vital role in industries like pharmaceuticals and cosmetics. Its thickening and stabilizing properties make it as versatile industrially as it is in your salad dressing!

Health Perspectives on Xanthan Gum

In terms of health, xanthan gum is generally seen as safe. While it may have some digestive effects for some people, its overall health profile is positive, especially given its low usage levels in food.

Alternative Thickeners and Stabilizers

If xanthan gum isn’t your thing, there are alternatives like psyllium fiber, chia seeds, and gelatin. Each has its own set of properties and uses, offering a range of options for your culinary experiments.

Conclusion

So, there you have it – the journey of xanthan gum from a bacterium’s byproduct to a key ingredient in your kitchen and beyond. It’s a fascinating journey of science, safety, and sustainability, showcasing how a tiny microbe can have a massive impact on our daily lives.

Ginhong, with its extensive experience and specialized equipment, plays a vital role in this process, showcasing how industry expertise can significantly impact production efficiency and product quality.