Want to know how to make shampoo (from scratch) that will eventually sell? Do you want to turn your homemade shampoo into an established brand? Afraid of stumbling upon the roadblocks most entrepreneurs face when they use the wrong type of equipment?

Consider this your ultimate guide in Shampoo Production!

In this article, you will learn the basic ingredients used by shampoo manufacturers and the proper manufacturing equipment for your hair-care business.

What You Should Know About the Shampoo-Making Niche

Nowadays, hygiene product staples such as the shampoos hit a tremendous demand spike due to the need to become clean to avoid contracting COVID-19.

According to a global survey, the shampoo market is expected to reach USD 1.48 Billion by 2024 at a CAGR of 9%.

Hence, if making and selling shampoo is your particular niche, you’ll have a considerable advantage over the market. You just need to formulate the right shampoo composition and order the proper machineries.

So first, let’s start off with the right shampoo formula.

Shampoo Ingredients List

It’s easy to find your local grocery aisle with lots of shampoo brand options, but the fact is, most of their components generally boil down to the same set of ingredients.

As Paula Begoun of Beautypedia points out, “All shampoo is essentially a cleanser.” She further says that “Only the first five or six ingredients impact the formula’s effectiveness.”

And when you actually compare these shampoo components, you’ll quickly be able to map a venn diagram of the 10 most similar ingredients.

Here are the most common ingredients found in most commercial hair shampoo recipes:

1. Deionized Water/Water

The most common shampoo ingredient, which makes up about 80% of the mixture. Without water or aqua acting as a solvent, the liquid for lathering will not flow out from the bottle.

2. Surfactants (Sodium Lauryl sulfates)

Surfactants strip away the dirt from the hair surface and bring it down with the water upon rinsing. They are detergents which make the hair squeaky clean. Surfactants are also the main ingredient in soaps, which make it bubble when you lather it to your wet skin.

3. Foaming Agent (Cocamidopropyl Betaine)

You’d mostly see Cocamidopropyl Betaine in many shampoo formulations, which provides the foaming or lathering feature. It also aids surfactants and thickens the mixture, making it viscous. It also conditions and softens the hair with its mild cleansing ability, giving a satisfying hair-washing experience

4. Conditioning Polymers (Polyquaternium)

This is frequently used in many personal care industries. It also helps in forming a film protection on the hair and provides an antistatic feature for better hair management.

5. Preservatives (Parabens)

You must have seen parabens in a lot of beauty products and not just in shampoos. They are frequently used as a preservative for cosmetic and personal care products to get rid of bacteria in the product. However, some forms of parabens have high estrogen components, which can lead to cancer. That’s why they are only added in very small amounts in the mixture to prevent any side effects on people.

6. Opacifying Pearling Agents

If you notice how shampoos have glossy, pearly appearance, it’s partly thanks to the pearling agent. Not only does it provide thickening texture, but also makes the shampoo less transparent and appear silky white.

7. Conditioning Emollients (Dimethicone)

We would cite Dimethicone as an example as it is mostly found in many shampoo formulations as the conditioning emollient. It provides moisturizing ability for the shampoo, and conditions the hair, making it feel smoother.

8. PH Adjuster (Citric Acid)

Citric Acid is the most common pH adjuster found in many shampoo constituents. In some labels, it’s named as sodium citrate.

Basically, it keeps your shampoo with the right level of acidity, which is usually 5.5 or lower. The acid reacts with the negative charge of the hair helping the cuticle or the surface layer of the hair keep a smooth surface.

9. Salt (Sodium Chloride)

You must be wondering why salt or Sodium chloride is needed in shampoo formulations. Sodium chloride makes the cuticle coarser so the hair can look fuller.

10. Fatty alcohols

Now you might wonder why alcohol, mostly considered to have drying effects on the skin, would be part of a shampoo formulation. But some alcohols, like Fatty Alcohols, serve as a moisturizing ingredient. You can find Panthenol, Cetyl Alcohol, Stearyl Alcohol or Cetearyl Alcohol in many cosmetic gels, creams and ointments, which actually bind water on the scalp or skin. Panthenol is a fatty alcohol providing vitamin B5.

Typical Shampoo Composition

Typically, you’d find the following haircare raw materials with ingredient substitutes/variations, but technically they serve the same purpose. At the right side of the table is how much each shampoo component usually contains in one production batch.

| Shampoo Ingredient | Variations in Shampoo Label | Percentage in the Solution |

|---|---|---|

| Water | Aqua, Deionized Water | 73-90% |

| Surfactant | Sodium/Ammonium Lauryl sulfates | 8-15% active |

| Foaming Agents | Cocamide or Cocamidopropyl Betaine, Lauryl/Coco Hydroxypropyl Sultaine, Disodium Cocoamphodiacetate, Cocamide MEA, and Decyl Glucoside | 2-6% active |

| Conditioning polymers | Guar Hydroxypropyltrimonium Chloride (the most popular), Polyquaternium 10, Polyquaternium 6, and Polyquaternium 7 | 0-1% |

| Preservatives | Methyl and propyl paraben, formaldehyde, Quaternium-15 | 0.001-1% |

| Opacifying Pearling Agents | Alkanolamides of higher fatty acids, propylene glycol, Mg, Ca and Zn salts of stearic acid, spermaceti, etc; Glycol Stearate | 0-1% active |

| Conditioning emollients | Typically Silicone or other minerals such as Lanolin, mineral oil, herbal extracts, egg derivatives | 0-1% |

| pH Adjuster | Citric acid | Proper quantity |

| Salt | Sodium Chloride | 0-2% |

| Fatty Alcohol | Panthenol, Cetyl Alcohol, Stearyl Alcohol or Cetearyl Alcohol | 4-5% |

Sidenote: If you want to know where to buy raw materials for your shampoo business, you can purchase them online at Making Cosmetics, Grapefruit or Amazon.

If you want to buy bulk raw materials at a cheaper cost, consider looking at Alibaba or Indiamart. However, purchasing in bulk requires a minimum order requirement (MOQ). So for beginners, you might want to buy in small quantities first.

It’s easy to get intimidated by the amount of shampoo vendors and brands with different formulations. But don’t be.

Almost all shampoo recipes have the same main ingredients, with just a tweak on the fragrance and features. Some are formulated with additional ingredients for anti-dandruff, anti-hair loss or others but they basically carry the same set of raw materials.

Now, it brings us to the question as to how you can formulate your own shampoo recipe. That is, if you don’t have any experience in making formulations.

Where to Get Shampoo Formulations?

We know you’ve stumbled upon a lot of promising homemade shampoo recipes on the internet, however, which ones are considered legit?

If you are a chemist or have a chemist background, it would be easier for you to know the proper formulation. If not, you can always hire someone to do it for you.

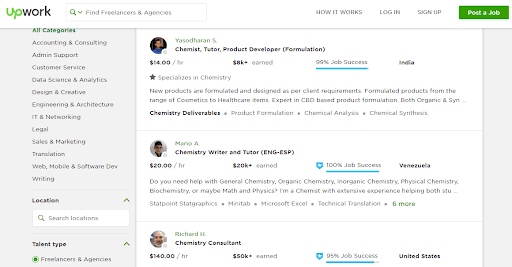

Finding a freelance chemist which can do shampoo formulations would be easier if you go to freelancing sites like Upwork.

If you choose this route, you would be spending around $1000 to $1500 per formulation.

Can I Make Formulations Based on Shampoo Homemade Recipes?

If you choose to make it on your own, you can do so as long as you do your research and let your product be tested or test it yourself (if you know how to culture cells).

While there’s no specific regulatory standards for shampoos before entering the market, some American and European associations do recommend stability testing for cosmetic manufacturers.

If you are planning to make anti-dandruff shampoos or shampoos with medical formulation, these would really have to undergo third-party testing as they are regulated as OTC drugs in the US.

If you’re serious about your shampoo line business, you might as well perform stability testing to make sure it’s safe for public use.

Shampoo Production Equipment: Machines You Need For Setting Up a Haircare Production Line

“Can I use a kitchen blender for mixing shampoo ingredients?”

“Is it necessary to buy the proper mixer to make shampoos?”

“How much does it cost to buy a shampoo mixing equipment?”

“Do I need to buy a shampoo filling and sealing machine?”

A lot of people tend to ask these questions before buying production equipment for shampoo, which Ginhong recommends you definitely should.In manufacturing shampoos, a typical production line consists of the following equipment:

- Mixing Equipment

- Packaging Equipment

- Filling Equipment

- Automatic Sealing Equipment

- Labeling Equipment

Shampoo Mixing Equipment

A Shampoo Mixer is where the mixing process takes place. It’s an industry-grade blender able to produce stable quality emulsions, which are critical in making shampoos.

The most common design has a mixer workhead, or a rotor-stator head, a slow-speed stirrer, a disperser, a motor and a transmission mount. Some design options include an automatic lifting system, a powder feeder and suction pump, load cells and a heating element.

The load cells are capable of automatically sensing accurate additions in kilos/lbs of shampoo raw materials added in one batch. Hence, you would not need to weigh each component in a separate weigher.

Investing in the right mixing equipment can homogenize and blend your hair care products more optimally. It improves your manufacturing quality, which helps you gain a good reputation for your product.

DO NOT USE THE KITCHENAID YOU USE FOR PREPARING MEALS FOR THE SAME PURPOSE OF MIXING SHAMPOO INGREDIENTS!

Food processors and kitchen blenders are meant for milling vegetables and food and are not designed for processing hair care raw materials.

On the other hand, industrial mixers are equipped with a rotor-stator homogenizer and a slow-speed agitator with scraper designed for milling and mixing shampoo ingredients. The disperser, or the saw-tooth impeller, is used when dispersing powders in the liquid.

This type of mixing equipment is what you also need when making cosmetics, creams, lipstick, nail polish, mayonnaise, hand sanitizer, toothpaste, etc.

Filling Equipment

Large manufacturing units of haircare products usually have automated filling machines to automatically fill bottles with pre-set volumes of shampoos. Filling machines have servo-motors and pneumatic devices which control the pumping of the liquid for filling bottles.

Normally, Shampoo filling machines are much needed in midsize to large scale shampoo businesses in order to meet hundreds to millions of inventories each month. It usually costs around $8,000 to $25,000 when you buy from China manufacturers.

Sealing Equipment

For automatically capping shampoo bottles, most large scale manufacturers use Sealing Machines. These are automated sealing equipment which secures the bottle cap with the body. They usually work at 40 to 100 shampoo bottles per minute.

A PLC program in Capping machines helps the operator make parameter adjustments such as the capping speed and bottle size changeover. Furthermore, capping machines have adjustable roller heads for accommodating different bottle cap diameters and heights.

A Shampoo Capping Machine usually costs around $5,000 to $10,000 per set.

Labeling Machines

Shampoo labeling and branding are just as important as good formulation and consistent mixtures. The label communicates what your shampoo recipe has to offer to your customers. It can also entice them whether your product is worth buying on.

An automatic labeler wraps labels on the cap and container. It is capable of working to over a thousand inventories per day. Only use this type of equipment if you are already selling products more than what you can handle to package yourself. It usually costs $5000 to $10,000 per set.

Shampoo Production If You’re Just Starting Out From Zero

We understand that some of you might be on a tight budget, right? But there is a solution. You can buy lab mixers from a reliable manufacturer in China.

Laboratory/Overhead Mixers: the Cheapest Mixing Equipment Option

Laboratory or Overhead mixers are high-energy, stainless steel mixers meant for small-scale production and testing of cosmetics and personal care products like shampoos. Options for load cells are available so you would not have to weigh ingredients in a separate scale balance.

If you buy from China mixer manufacturers, these usually cost around $300 to $7,000 per unit, depending on the type, quality and features. Using an appropriate high shear lab mixer for small-scale shampoo production gives you the advantage of:

- Testing your ingredients first if they form stable emulsions,

- Testing the market with your small batches of manufactured shampoos,

- Producing consistent product mixtures at a low budget, but with high quality.

- Using the appropriate tool for making emulsions.

Should I Invest in Packaging Machines?

You can skip on the shampoo filling and sealing machine if you are just starting out from scratch. You can manually fill screw-cap bottles yourself and stick manually stick the labels on the bottles.

But if you start making money and want to scale-up your business, you will need to buy larger mixing tanks or batch mixers and filling and sealing machines and labelers.

How to Test Your Shampoo Product?

Whether you hire a chemist to formulate your shampoo or you do it yourself, it is safe to have it officially tested for quality. Shampoo formulations should be medically safe for consumer use.

Most manufacturers employ the help of third party testing facilities to test their products. However, you can test your products yourself before you bring samples to third party facilities to save time and money.

When you pass the right tests for your product, you wouldn’t have to face any possible lawsuits.

For shampoo testing and other cosmetic tests, Stability Tests, Microbiological Tests and Packaging Stability Tests are usually performed.

What Testing Tools You Will Need?

To perform part of these tests yourself/in-house, you will need the following materials:

- Digital Scale

- Incubator (-10 to 50C temperature range)

- Viscometer

- Microbial Test Kit – you can buy this from Formulator Sample Shop at $32.

Stability Test

Stability test evaluates the product at varying environmental temperatures and conditions. Basically, you would have to undergo three phases: chemical, physical and integrity tests. Under these tests, the color, viscosity, flow, fragrance, pH, texture, and emulsion stability are evaluated.

For physical stability tests, you can carry out Accelerated Stability Testing. This evaluates the shelf life of your product under controlled temperature and humidity. You would need to buy an Incubator to do this. You would need to isolate your product samples at 37°C, 40°C or 45°C up to 3 months.

Microbiological Test

On the other hand, Microbiological Tests assess the degree to which your product can prevent microbial growth during usage. There are microbial testing kits available in the market, which you can easily use. Sampling and assessment is simple and can be performed even without training. You just need to follow simple instructions.

Packaging Stability Test

Packaging stability test evaluates the effect of the container on the product. It also evaluates the effect of the external environment on the product once you open it from the packaging.

To Sum Up

How to produce shampoo from scratch and make it sell is a long and painful process from the formulation stage, to acquisition of your raw materials, to the mixing process, to packaging and to testing. We hope this guide helped you choose which equipment you need in making shampoos.

Ginhong is an experienced shampoo mixer manufacturer in China where you can buy professional cosmetic production equipment. If you want to start your shampoo business today, don’t hesitate to discuss your ideas with us so we can give suggestions on what mixer specifications you need.