Have you ever wondered how smoothies are made from raw ingredients to that delicious, creamy drink?

Smoothies are made by blending fresh or frozen fruits and vegetables with a liquid, such as milk, juice, or yogurt. People usually add other ingredients like nut butter, protein powder, seeds, or spices according to the flavors they prefer.

To make the smoothie, you just add all these ingredients with a commercial blender until the ingredients become smooth.

How you add each ingredient affects its texture so it’s best to add the liquid first then the softest ingredients. Afterward, follow with the firmest ingredients.

In a factory setting, this process is adapted for large-scale production. Here, industrial-grade blenders and mixers are used to handle larger quantities of ingredients.

However, these basic principles remain the same – combining fruits, vegetables, liquids, and other additives – but the scale is significantly larger.

The Key Ingredients

Smoothie-making starts with quality ingredients – fresh fruits, vegetables, and a liquid base like water, juice, or milk. In a factory setting, these ingredients might be whole or as preprepared purées.

Smoothies often include grains, herbs, or proteins to boost their nutritional value. Unlike juices, smoothies have a thicker consistency, thanks to the natural thickening effects of ingredients like bananas and mangoes.

How are Smoothies Made in a Factory?

Factories making smoothies blend these components, adjusting the recipe to achieve that perfect, smooth texture we all love.

Some manufacturers use whole fruits and veggies, while others prefer preprepared purées. The equipment and methods vary, but the goal is the same: a perfectly blended smoothie.

Whether it’s a small batch in a café or large-scale production, the challenge is to blend liquids of different viscosities and incorporate powdery ingredients like milk powders seamlessly.

Here’s a step-by-step process of Smoothie Manufacturing:

1. Cleaning and Preparing Ingredients

The initial step in smoothie manufacturing involves meticulous cleaning of fruits and vegetables. This is crucial for removing potential contaminants like pesticides and soil. Commercial washers use specialized jets and brushes to thoroughly clean the produce. Peeling and cutting, particularly for larger fruits and vegetables, are often automated processes that help standardize the size of the ingredients, ensuring consistent blending and flavor.

2. Mixing the Ingredients

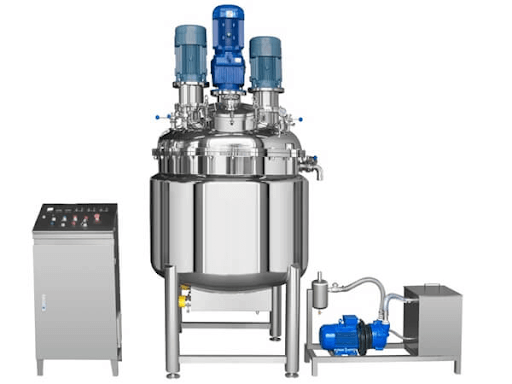

In the blending phase, ingredients are added to large industrial blenders. The key here is the use of high-shear mixers, which are essential for breaking down fibrous fruits and vegetables into a smooth consistency.

High-shear mixers work by generating intense shear forces through rapidly rotating blades, creating a vortex that homogenizes the mixture.

This process ensures that all components, including solid fruits, leafy greens, and even seeds or nuts, are uniformly blended, contributing to the smooth texture and consistent taste of the smoothie.

3. Sterilizing the Smoothie (Pasteurization)

Pasteurization is a critical step to ensure the safety and extend the shelf life of the smoothie. This involves heating the smoothie to a specific temperature to kill harmful bacteria. There are different methods of pasteurization:

4. Batch Pasteurization

This traditional method involves heating the smoothie in large tanks for a set period. It’s suited for smaller batches and allows for precise control over the heating process.

Continuous Flow Pasteurization: In this method, smoothies are pasteurized in a continuous stream, making it more efficient for larger volumes.

High-Temperature Short-Time (HTST): Often used in beverage processing, this method rapidly heats the smoothie for a very short duration, which is effective in preserving the nutritional quality and taste while ensuring safety.

5. Packaging Process

The packaging phase is not just about putting the smoothie into bottles or cartons; it’s also about maintaining its quality. Modern filling machines are designed to handle various viscosities, ensuring each container has a precise amount of smoothie. These machines also need to maintain hygiene standards to prevent contamination.

6. Storage and Distribution

Post-packaging, smoothies are stored in temperature-controlled warehouses. This is crucial to prevent spoilage and maintain the quality of the product. Refrigerated logistics play an essential role in ensuring that smoothies reach consumers while still fresh. The entire supply chain is designed to maintain a cold environment, preserving the smoothie’s taste and nutritional value.

Equipment and Technology in Smoothie Making

Scaling up from a small test batch to large-scale production is tricky. Achieving the same texture and flavor batch after batch can be a hurdle.

And here’s a fun fact: those conventional agitators you see? They struggle to blend liquids of varying thicknesses, making the process longer and trickier.

Enter high-shear mixers, like the Ginhong mixers. These mixers are changing the game in smoothie production. They’re capable of rapidly disintegrating fruits and vegetables, ensuring a smooth, consistent mixture every time. No more worrying about bits of unblended fruits or uneven textures!

- For Purées and Juices: The blending equipment must handle liquids with a broad spectrum of viscosities.

- For Whole Fruits and Vegetables: A variety of machinery may be required, particularly for processing frozen, hard, or fibrous ingredients. This equipment is designed to chop and purée these items effectively.

- Incorporating Powdered Ingredients: The blending system should efficiently disperse any powdered additions like milk powders or nutritional supplements, ensuring even distribution throughout the smoothie.

Challenges in Smoothie Manufacturing

Smoothie production can encounter several issues:

- Scaling Problems: Small-scale blending equipment often lacks a direct equivalent in large-scale production, making it challenging to replicate small-batch results in larger operations.

- Consistency Issues: Achieving repeatability between different production batches can be difficult.

- Texture and Mouthfeel: Inadequate processing might result in an undesirable texture and mouthfeel in the final product.

- Blending Difficulties: Traditional agitators struggle with blending liquids of significantly different viscosities, potentially necessitating extended mixing times.

- Incorporating Powdered Ingredients: Adding powders to thicker smoothies can be particularly challenging, as they require thorough dispersion to avoid clumping.

The Solution: Ginhong High Shear Mixer

Ginhong’s range of industrial mixers, including vacuum emulsifier homogenizers, high shear mixers, multi-shaft mixers, and planetary mixers, are instrumental in achieving the perfect consistency and texture in smoothies.

The smoothie manufacturing industry faces various challenges, from ensuring consistency in large-scale production to maintaining the nutritional integrity of ingredients.

Ginhong’s mixers address these challenges, providing solutions that streamline the manufacturing process while maintaining the quality of the final product.

A potential solution to these challenges is the use of a Ginhong High Shear mixer, which operates in the following stages:

- Initial Mixing: The liquid is first added to the vessel, and the mixer is activated. Fruits and/or vegetables are then introduced and swiftly disintegrated within the rotor/stator workhead.

- Intensive Shearing: Driven by centrifugal force, the ingredients move towards the outer part of the workhead, encountering intense shearing in the gap between the rotor and the stator. This process forces the product out of the stator, spreading it uniformly back into the mix.

- Continuous Blending: New materials are consistently drawn into the workhead. In a brief yet efficient mixing cycle, the ingredients pass repeatedly through the workhead, achieving a smooth and even blend.

Conclusion

Smoothies are indeed a great way to enjoy a variety of fruits and vegetables. They can be tailored to dietary needs or flavor preferences, making them a versatile option for any meal or snack. Your basic smoothie recipe is a great starting point for anyone new to smoothie making, offering a balance of fruitiness, creaminess, and nutrition.

For those interested in exploring further, there are many ways to experiment with smoothie ingredients. Some might add superfoods like chia seeds or matcha powder, while others might opt for a vegan version using plant-based milk and yogurt. The possibilities are endless, allowing everyone to find their perfect smoothie match!