Ever wondered how hummus is made? It’s very simple! Whether you’re making hummus at home or commercially, we’ve got you covered in this article on how hummus is made.

This creamy, flavorful spread, a staple in Middle Eastern cuisine, has won hearts globally. Let’s dive into the world of hummus and explore how this delicious dip goes from simple ingredients to a bowl of yummy goodness.

Key Takeaways:

- Discover how chickpeas, the heart of hummus, are transformed into this beloved spread.

- Learn about the role of tahini in adding richness and unique flavor to hummus.

- Explore the innovations in hummus production, including new flavors and nutritious ingredients.

Homemade vs. Factory-Made Hummus

Homemade hummus usually involves fresher, simpler ingredients. Home cooks often prefer using organic or locally sourced ingredients.

The choice of ingredients can be more flexible, allowing for the use of the following:

- fresh lemon juice,

- different types of tahini, or

- heirloom chickpea varieties

The process is more hands-on and can be adjusted according to personal preferences. For example, the amount of time chickpeas are soaked and cooked can be varied. Blending in a home kitchen typically involves a food processor or blender, and the texture can be adjusted by blending for longer or shorter periods.

Moreover, homemade hummus often has a slightly less uniform texture, which some people prefer for its authentic feel. The flavor can be adjusted with each batch, allowing for more garlic, lemon, or tahini according to taste.

The Primary Ingredients of Hummus

1. Chickpeas (Garbanzo Beans)

Chickpeas are the foundation of hummus. They are high in protein and fiber, giving hummus its hearty, satisfying nature. Typically, they are soaked and cooked until tender before being blended. The quality and preparation of chickpeas greatly influence the texture and taste of the final product.

2. Tahini

This paste made from ground sesame seeds is a key ingredient that differentiates hummus from other bean dips. It adds a rich, nutty flavor and contributes significantly to the creamy texture of hummus. The quality of tahini can vary, so selecting a good brand can have a noticeable impact on the taste.

3. Olive Oil

Olive oil is used for its flavor and smooth texture. In traditional hummus recipes, it is often mixed into the hummus and also drizzled on top before serving. The type of olive oil used can impart different flavor notes, from fruity to peppery.

4. Lemon Juice

Fresh lemon juice is crucial for adding a bright, tangy flavor that cuts through the richness of the tahini and chickpeas. It balances the flavors and adds a refreshing note. The amount of lemon juice can be adjusted based on personal preference for tanginess.

5. Garlic

Garlic adds a pungent depth to hummus. It can be adjusted according to taste, with some recipes calling for raw garlic for a sharper bite, while others use roasted garlic for a more mellow, sweet flavor.

6. Salt

Salt is essential for bringing out the flavors of the other ingredients. It’s important to season hummus properly as it can be quite bland without sufficient salt. Some recipes might also include a pinch of black pepper or other seasonings.

7. Water or Aquafaba

Water is sometimes added to adjust the consistency of hummus, making it smoother and easier to blend. Aquafaba, the liquid from canned chickpeas, is a popular alternative as it contains starches that contribute to a creamy texture and can help emulsify the ingredients.

8. Spices

Spices like cumin and paprika are often added to hummus for their warm, earthy flavors. Cumin adds depth and a slight smokiness, while paprika can add color and a mild, sweet pepperiness. Some recipes also include a pinch of cayenne pepper for heat.

How is Hummus Made? The Hummus Manufacturing Process

1. Ingredient Sourcing and Preparation

The journey of hummus begins with preparing the chickpeas. They’re soaked in water, sometimes with a bit of baking soda, to soften them up. Then, they’re cooked until perfectly tender.

- Chickpeas: Factories usually buy chickpeas in bulk. These are sorted to remove any debris or poor-quality beans and then soaked in water, sometimes with added baking soda, to soften them. This soaking process can take up to 12 hours.

- Tahini: High-quality tahini is sourced, which is essential for the flavor and texture of hummus. It’s often stored in large containers to be readily used in the production line.

- Other Ingredients: Fresh ingredients like lemons and garlic are sourced. Spices such as salt, cumin, and paprika are also prepared in measured quantities for consistency in flavor.

2. Cooking

The soaked chickpeas are transferred to large steam cookers or pressure cookers. They are cooked until they become soft and tender, a crucial step for achieving the right texture.

3. Grinding & Blending

The cooked chickpeas are then blended in industrial mixers. Tahini, olive oil, lemon juice, minced garlic, salt, and other spices are added during this process. The blending must be thorough to achieve a smooth, consistent paste. The proportions and blending time are carefully controlled to ensure product consistency.

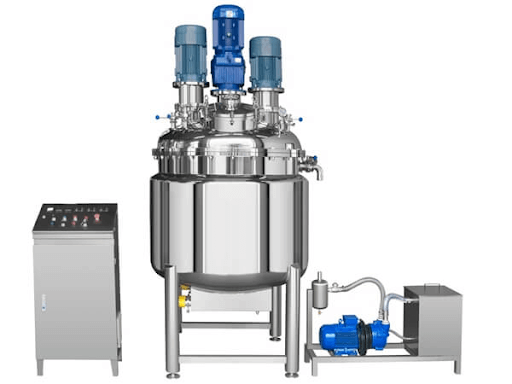

Since mixing is a crucial process, an advanced mixing process is needed:

- Homogenization: The chickpea paste is transferred to a mixing tank where a high-shear mixer is used. This equipment is designed to homogenize the mixture, breaking down any remaining chickpea particles to achieve a smooth consistency.

- Integration of Tahini and Oil: Tahini and olive oil are gradually added to the mixture. The high shear action of the mixer ensures these ingredients are thoroughly blended with the chickpea paste. This is crucial for the emulsification process, where oil and water-based components are uniformly dispersed.

- Adding Liquids and Seasonings: Water, lemon juice, and other liquid ingredients like aquafaba are added next. The high-speed rotation ensures that these ingredients are evenly distributed throughout the mixture. Spices and seasonings are also added during this stage, with the mixer ensuring even distribution without clumping.

4. Taste and Quality Control

Samples from each batch are tested to ensure they meet the factory’s standards for taste, texture, and quality. Adjustments may be made to the recipe based on this feedback.

5. Packaging

The hummus is then moved to the packaging line, where it is filled into containers. This process is automated to ensure efficiency and hygiene. The containers are sealed and labeled.

6. Pasteurization or Sterilization:

To extend shelf life and ensure safety, some factories use pasteurization or sterilization techniques. This process kills any harmful bacteria without significantly affecting the taste or texture of the hummus.

7. Cooling and Storage

The packaged hummus is cooled to a safe storage temperature. It is then stored in a refrigerated area to maintain freshness until distribution.

8. Distribution

Finally, the hummus is shipped to various retail locations. Temperature-controlled transportation ensures the product remains fresh until it reaches the consumer.

9. Innovation and Flavor Variation

Many factories also engage in creating different flavors of hummus, such as adding roasted peppers, herbs, or experimenting with alternative ingredients like edamame. This process involves recipe development and additional taste testing to refine new flavors.

Conclusion

Whether it’s the home cook carefully balancing flavors in their kitchen or a large-scale production in a factory, the essence of making hummus remains the same – blending simple, wholesome ingredients into a creamy, flavorful delight.

Factory-made hummus involves a more controlled, scientific approach. Large-scale manufacturers like Ginhong, a leading mixer and homogenizer manufacturer, play a crucial role in ensuring that hummus is produced efficiently and uniformly.

Ginhong’s advanced mixing equipment, such as our high-shear mixers, tackles the challenges of large-scale hummus production. Our industrial mixers ensure thorough blending and homogenization of ingredients, achieving the perfect balance of flavors and textures in every batch. Contact us for a quotation!