Discover how ketchup is made in a modern factory. Which manufacturing equipment (mixers, filling, sealing machines) are used? Find out below!

Ketchup, the beloved tangy condiment, is a staple in American households and a favorite accompaniment to classics like hamburgers, hot dogs, and french fries. However, have you ever wondered how this iconic sauce comes to life?

In this article, we’ll take you on a journey from the fascinating history of ketchup to its modern-day manufacturing process. You’ll discover the meticulous craft behind this humble yet ubiquitous condiment.

Key Takeaways

- Ketchup production is a meticulous process that involves various ingredients such as tomatoes, sugar, vinegar, spices, and seasonings.

- Mixing equipment plays a crucial role in ketchup production, ensuring the right consistency and quality of the final product.

- Ginhong offers a range of ketchup mixing equipment to cater to different batch sizes, ingredients, and viscosity requirements.

- High-shear mixers, in-line mixers, Flashmix mixers, and vacuum homogenizer ketchup mixers are versatile solutions for various ketchup production needs.

- The choice of mixing equipment can significantly impact the efficiency, quality, and consistency of the ketchup manufacturing process.

A Tangy History: When was ketchup made?

Ketchup’s story is a testament to its enduring popularity. While we primarily associate it with tomatoes today, its origins stretch back to ancient China, where it began as a brine of pickled fish or shellfish known as “ke-tsiap.” The concept of ketchup soon spread to neighboring countries, each adding their own twist by incorporating various herbs, spices, and even fish brine.

In the late 1600s, English sailors traveling through Malaysia and Singapore encountered this exotic sauce and brought samples back to England. However, without access to some of the original ingredients, English cooks had to improvise, using ingredients like cucumbers, almonds, mushrooms, and oysters to recreate the spicy sauce.

One hundred years later, New Englanders introduced tomatoes to the ketchup equation, marking a turning point in ketchup’s history. The tangy tomato ketchup quickly gained popularity and became a favorite accompaniment for various dishes, including codfish cakes and meat.

The Ingredients of Ketchup

Ketchup’s tantalizing flavor comes from a blend of key ingredients. The main components include tomatoes, sweeteners, vinegar, salt, spices, and flavorings. While tomatoes are the star, other crucial ingredients like granulated cane sugar, vinegar, and a mix of spices such as allspice, cassia, cinnamon, cayenne, cloves, pepper, ginger, mustard, and paprika contribute to the distinctive taste.

The proportions of these ingredients may vary between different ketchup brands, as they strive to achieve specific textures and consistencies. Some manufacturers prefer using whole spices for a milder and more flavorful taste, while others opt for premixed or encapsulated spices for convenience.

How Tomato Ketchup Is Made In Factory

Now, let’s dive into the heart of ketchup production – the manufacturing process.

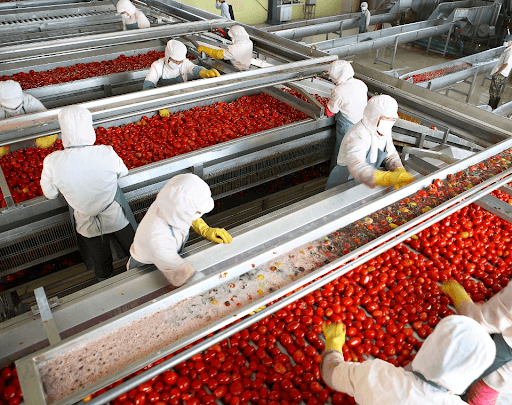

1. Preparing Quality Tomatoes

The foundation of ketchup is quality tomatoes. Varieties are developed for superior color, flavor, texture, and yield. Consistency in tomato characteristics is vital to maintain the flavor and color of the final product.

2. The Pulping Process

Tomatoes are harvested, washed, and conveyed to flumes, protecting them from damage. Inspectors ensure that the tomatoes meet initial requirements. The tomatoes are sorted, washed, and chopped. They undergo pre-cooking in stainless steel vats, preserving them and eliminating bacteria.

3. Adding Ingredients and Cooking

The tomato pulp is heated to boiling in cooking tanks or kettles. Precise amounts of sweeteners, vinegar, salt, spices, and flavorings are added. The timing of adding spices is crucial, as is avoiding excessive evaporation. Onions and garlic are added, and the mixture is cooked with temperature control to prevent overcooking.

4. Finishing for the Perfect Consistency

The ketchup mixture goes through a finishing process, removing excess fiber and particles. Some ketchups are milled to achieve a smoother consistency.

5. De-Aeration and Filling

De-aeration is essential to prevent discoloration and bacterial growth. Containers are filled with ketchup at a controlled temperature and sealed to preserve freshness.

6. Cooling, Labeling, and Packing

Ketchup containers must be cooled to prevent flavor loss. They are labeled with product information before shipping.

This entire manufacturing process generally takes two to three hours, and the quality of ingredients is a priority.

The Crucial Part: The Mixing Process

Ketchup’s heart lies in the intricate mixing process, where concentrated tomato paste is harmoniously blended with water, sugar, vinegar, salt, and a medley of seasonings. The primary tomato paste is typically created using the “Hot Break” method, a crucial technique in ketchup production.

With the “Hot Break” method, pulped tomatoes are meticulously heated to around 200˚F (90˚C).

This gentle heating not only preserves the natural pectin found in tomatoes but also ensures that some of the aroma and color are retained. It’s this balance of preservation and transformation that contributes to the exceptional quality of premium ketchup with a high solids content.

The viscosity of top-tier ketchup hinges on a delicate interplay. It arises from the water retention of the fibrous strands in the tomato paste and the gelling effect of the pectin. The pectin is released through a process known as high-pressure homogenization. Ketchups with lower solids content may incorporate starch-based thickeners or gums to achieve their desired consistency.

The Process

The crafting of ketchup is a fascinating blend of art and science, and recipes, viscosities, and solids content can vary widely. Here’s how the magic unfolds:

- Utilizing Natural Pectin: When the natural pectin in the paste acts as a thickening agent, the fibrous strands in the tomatoes need to be fibrillated, or gently frayed. This process boosts the paste’s capacity for water retention, subsequently increasing viscosity. After the ingredients are mixed, the product undergoes high-pressure homogenization to attain the desired consistency. This method also enhances yield, allowing for a thicker product even with lower solids content.

- Using Thickeners: In another method, high-pressure homogenization is bypassed, and thickening agents such as xanthan gum, pectin, or starch (including modified starches) are introduced to achieve the targeted viscosity in the final ketchup. The mixing apparatus in this case must be adept at dispersing powdered ingredients into water to create a product that’s free of agglomerates.

The Problem

While crafting this beloved condiment, several challenges may arise, especially when conventional agitators are used in the mixing process:

- Lengthy Mixing Times: Traditional agitators often require an extended duration to blend tomato paste into water, particularly when dealing with liquids of vastly differing viscosities.

- Agglomerate Formation: Additives designed to thicken the product may form agglomerates that agitators struggle to disintegrate.

- Build-Up of Ingredients: Partially hydrated ingredients can accumulate on the vessel wall and within the mixer, potentially leading to inconsistent results.

- Uniform Pre-Mix Requirement: A uniform pre-mix is necessary for the homogenizer, but agitators often fall short in achieving this uniformity.

- Dulling Finish: Homogenization and other handling processes can inadvertently dull the finish of the ketchup, compromising its visual appeal.

The Solution

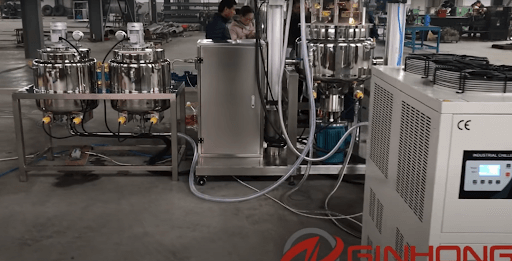

The solution to these challenges lies in the remarkable capabilities of a Ginhong high shear mixer, which not only eliminates these problems but also streamlines the production process:

- Stage 1: The journey begins with the vessel being filled with water, and the Ginhong mixer is set into motion. Powdered ingredients are gently added. The high-speed rotation of the Ginhong mixer creates a robust suction force that efficiently draws both the liquid and powders into the workhead. The materials within the workhead experience intense shear forces.

- Stage 2: The process continues as agglomerates are masterfully disintegrated between the ends of the rotor blades and the stator wall. The product is then propelled out through the stator, rejoining the mix. Meanwhile, fresh materials are seamlessly drawn into the workhead, perpetuating the mixing cycle. This circulatory mixing pattern ensures rapid and complete hydration of the thickening agents.

- Stage 3: As the final, crucial step, tomato paste is introduced and dispersed in the same manner. This meticulous process results in a homogenous mixture of ketchup that’s quickly achieved, maintaining the condiment’s desired texture and quality.

The Ginhong high shear mixer serves as a vital tool in ketchup production, alleviating common challenges and ensuring a consistently high-quality end product that retains its freshness and visual appeal.

Quality Control and Sustainability

To ensure the quality of ketchup, samples are taken at various production stages. Tomato growers must adhere to regulations regarding fertilizers and pesticides. Oxidation can affect ketchup’s color, but de-aeration during manufacture helps prevent this. Ketchup makers also maintain consistency in color and flavor through the concentration of tomato solids in the mixture.

Ginhong Ketchup Mixing Equipment Product Range

Selecting the appropriate industrial mixer for ketchup production hinges on several factors, including batch size, ingredient formulation, and the desired viscosity of the final product. Ginhong provides a diverse array of mixers within its product range to cater to your unique ketchup processing needs:

1. High Shear Batch Mixers

Ideal for small ketchup batches, typically ranging up to 50 – 80 US gallons, these mixers are perfectly suited for the production of specialty ketchups. They come with the added convenience of being mountable on mobile floor stands, allowing for easy relocation from one vessel to another.

2. High Shear In-Line Mixers

When dealing with larger ketchup batches, these mixers offer an effective solution. They can be easily integrated into your existing production setup. In combination with an efficient in-tank agitator, these in-line mixers efficiently disperse powders, ensuring the ketchup mixture remains free of aeration. Typically pump-fed, these mixers can also facilitate vessel discharges. Additionally, Ginhong offers Ultra Sanitary and High Viscosity models to suit specific production requirements.

3. Powder-Liquid Mixer/Flash Mixer

For ketchup batches containing substantial volumes of powders, Flashmix mixers are a reliable choice. They excel in minimizing aeration and reducing the cleaning demands of the equipment. Moreover, you can regulate the rate of powder addition, making these mixers an excellent fit for higher viscosity ketchup blends, even when processing at elevated temperatures. With minimal operator intervention, Flashmix mixers maintain product consistency.

4. RX Vacuum Homogenizer Ketchup Mixer

Ginhong’s RX Vacuum Homogenizer Ketchup Mixer Machine stands as the ultimate solution for crafting a wide spectrum of ketchup formulations, from smooth-textured to those with small particulates. This versatile piece of equipment marries a vacuum-filled blender with an emulsifier and homogenizer, enabling the creation of ketchups enriched with diverse ingredients such as natural components, oils, spices, and powders, thereby allowing you to attain your desired flavor profile with precision.

The Vacuum Homogenizer Ketchup Mixer can be meticulously controlled to align with your specific mixing requirements, including shear rate and heat-treatment, ensuring the desired consistency of the final product. The vacuum feature enhances product quality by enhancing the efficiency of distributing powder ingredients throughout the ketchup mixing process.

Frequently Asked Questions (FAQs) About Ketchup Production

1. How Is Ketchup Made In A Factory?

In a modern ketchup factory, the production process begins with harvesting quality tomatoes. These tomatoes undergo sorting, washing, and chopping, followed by pre-cooking in stainless steel vats to preserve them and eliminate bacteria. Afterward, precise amounts of sweeteners, vinegar, salt, spices, and flavorings are added. The mixture is heated to boiling in cooking tanks or kettles with temperature control. The ketchup mixture then goes through a finishing process to remove excess fiber and particles. It is de-aerated to prevent discoloration and bacterial growth, filled into containers at a controlled temperature, labeled, and packed.

2. How Is Tomato Sauce Made Step By Step?

Making tomato ketchup, a type of tomato sauce, involves a step-by-step process. It starts with the selection of quality tomatoes with superior color, flavor, and texture. These tomatoes are harvested, washed, and processed to eliminate impurities. Tomato pulp is then cooked and mixed with sweeteners, vinegar, salt, spices, and flavorings. After achieving the desired consistency, the ketchup is de-aerated, cooled, and packaged for distribution.

3. How Ketchup Is Made From Tomatoes?

Ketchup is primarily made from tomatoes, typically using a tomato paste created using the “Hot Break” method. Pulped tomatoes are meticulously heated to around 200˚F (90˚C) using this technique. This gentle heating preserves the natural pectin found in tomatoes, ensuring that some of the aroma and color are retained. The viscosity of ketchup comes from the water retention of the fibrous strands in the tomato paste and the gelling effect of the pectin, which is released through high-pressure homogenization. Ketchups with lower solids content may incorporate starch-based thickeners or gums to achieve their desired consistency.

4. How Is Commercial Ketchup Made?

Commercial ketchup production is a result of the transition from homemade to mass production. Companies like H.J. Heinz Co. played a significant role in this transition. They introduced classic narrow-neck bottle designs and innovative packaging methods. Initially, glass containers sealed with cork and dipped in wax provided a safe and airtight environment for ketchup. Later, the introduction of screw caps and plastic squeezable containers revolutionized ketchup packaging.

5. What Is Ketchup Made Out Of?

Ketchup is made from a blend of key ingredients, including tomatoes, sweeteners, vinegar, salt, spices, and flavorings. While tomatoes are the star ingredient, others like granulated cane sugar and a mix of spices contribute to its distinctive taste. The proportions of these ingredients may vary between different ketchup brands to achieve specific textures and consistencies. Some manufacturers use whole spices for a milder and more flavorful taste, while others prefer premixed or encapsulated spices for convenience.

6. How is ketchup usually packaged?

Ketchup packaging is designed for preservation, convenience, and different use cases. The most common types include:

- Plastic Squeeze Bottles: The most popular choice for home use, these are lightweight, durable, and easy to handle, often featuring upside-down designs and stay-clean caps.

- Glass Bottles: The classic and traditional option, glass is recyclable and excellent for preserving flavor, though it is heavier and more fragile than plastic.

- Single-Serve Packets: These small foil or plastic packets are standard in restaurants and fast-food establishments for portion control and hygiene.

- Bulk Containers: For the foodservice industry, ketchup is supplied in large jugs, pouches, and bag-in-box systems. This type of food packaging in wholesale is designed for high-volume use in commercial kitchens and dispenser machines, focusing on cost-effectiveness and efficiency.

Conclusion

In conclusion, ketchup is more than just a condiment; it’s a product of centuries of history and fine craftsmanship. Its evolution from a simple fish brine to the modern, convenient bottle on your table represents innovation and a desire to meet consumer needs. Next time you enjoy a dollop of ketchup, remember the artistry that goes into making this beloved condiment.