High Shear Colloidal Mixers

For applications where stability, fineness, and uniformity are essential, Ginhong’s high shear colloidal mixers provide the advanced shear power needed to produce nano-scale suspensions and fine colloidal dispersions. These mixers are widely used in pharmaceuticals, cosmetics, food processing, and chemical industries.

Are You Looking for A Reliable Supplier of Mixers?

What is a High Shear Colloidal Mixer?

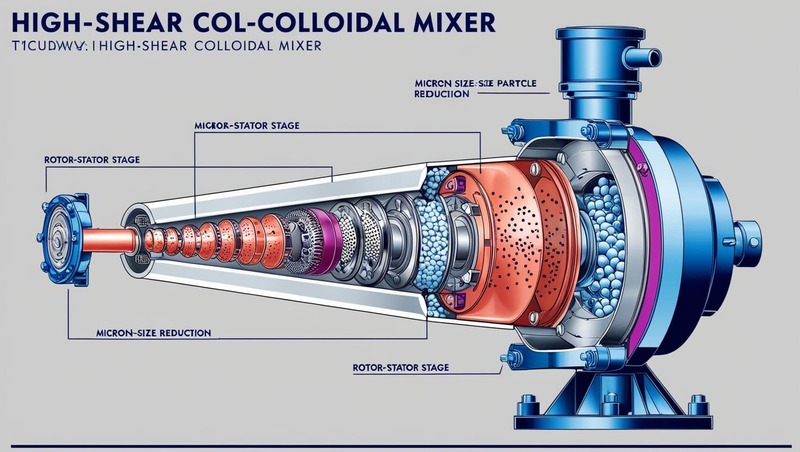

A high shear colloidal mixer is a specialized rotor-stator system designed to reduce particle and droplet size to the colloidal range—often below 1 micron.

These mixers create strong mechanical and hydraulic shear forces, ideal for creating fine emulsions, stable suspensions, and colloidal solutions.

How It Works

Colloidal mixers operate using high-speed rotors inside precision-engineered stators.

As materials are pumped through the narrow gaps, intense shear breaks down particles and droplets to colloidal size. The result: extremely fine and uniform mixtures with long-term stability.

Features & Benefits

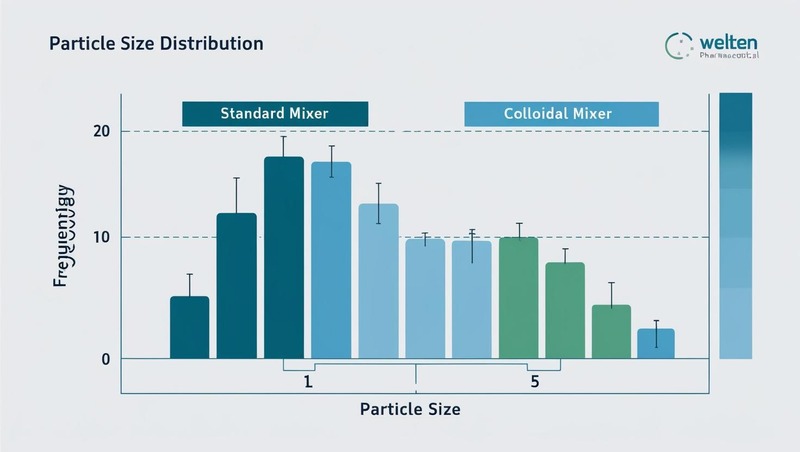

These mixers are particularly effective in applications requiring uniform particle size distribution and high emulsion or suspension stability.

- Submicron particle and droplet size

- Multi-stage shear zones for precision control

- Suitable for both batch and inline systems

- Supports heat-sensitive and high-viscosity materials

- Enhances bioavailability, texture, and shelf life

How to Choose the Right Colloidal Mixer

Ginhong engineers can tailor colloidal mixing systems to your specific dispersion or emulsion goals.

- Desired particle/droplet size: Select appropriate rotor-stator geometry for your micron range target.

- Viscosity and material compatibility: Ensure the mixer can handle thick or abrasive components.

- Batch vs. continuous flow: Choose based on production scale and formulation stability.

- Thermal sensitivity: Opt for jacketed vessels or vacuum options for heat control.

- Regulatory compliance: Match with cGMP or food-grade requirements as needed.

Typical Applications

- Pharmaceuticals: Injectable emulsions, suspensions, nanodrug carriers

- Cosmetics: Nano-emulsions for serums, liposomes, and active delivery systems

- Food & Beverage: Flavor emulsions, beverage clouding agents, dairy drinks

- Chemical: Pigment suspensions, polymer dispersions, surfactant solutions

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

Video: See It In Action

Watch how colloidal mixers achieve nano-level dispersion and ultra-smooth emulsification:

FAQs

What particle size can a colloidal mixer achieve?

What makes a mixer “colloidal”?

Are these mixers suitable for pharma or cosmetic formulations?

Can I use colloidal mixers for heat-sensitive materials?

What’s the difference between a colloidal mixer and a homogenizer?

Need a solution for ultra-fine dispersion and formulation stability? Contact Ginhong to build your custom high shear colloidal mixing system.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589