High Shear Rotor Stator Mixers

Ginhong’s high shear rotor stator mixers are the heart of many modern emulsification, dispersion, and homogenization processes. Designed for accuracy, speed, and consistency, these mixers are used across cosmetics, pharmaceuticals, food, and chemical industries to break down particles, reduce droplet sizes, and create stable emulsions.

Are You Looking for A Reliable Supplier of Mixers?

What is a High Shear Rotor Stator Mixer?

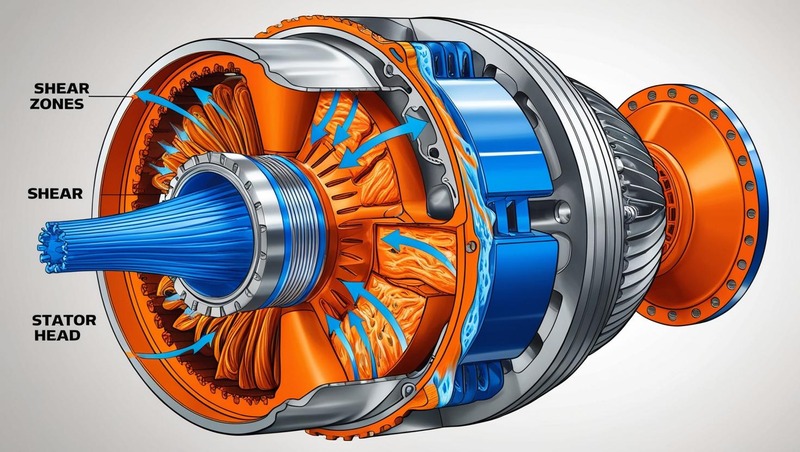

A high shear rotor stator mixer consists of a rotating impeller (rotor) that spins inside a fixed housing (stator) with tight tolerances.

This configuration generates intense mechanical shear as fluid is drawn into the mixing head and forced through the narrow gaps.

How It Works

The rotor pulls liquid and solid components into the head and propels them through the stator’s perforations at high speed.

This shearing action creates turbulence, breaks apart agglomerates, and disperses or emulsifies the ingredients uniformly.

Features & Benefits

These mixers are trusted in applications where product texture, particle size, and batch repeatability matter most.

- Consistent shear zones for controlled mixing

- Rapid dispersion and emulsification

- Available in batch and inline formats

- Handles a wide range of viscosities

- Modular heads for customization to process needs

How to Choose the Right Rotor Stator Mixer

- Viscosity and shear sensitivity: Choose head geometry and speed accordingly.

- Batch size or flow rate: Determine whether batch or inline configuration suits your process.

- Emulsion or dispersion target: Different stator designs support different applications.

- Cleaning needs: Look for CIP-ready models with sanitary construction.

- Material compatibility: Match stainless steel grade or Hastelloy to your formulation.

Our team can help configure a rotor stator system that meets your technical and regulatory requirements.

Typical Applications

- Cosmetics: Emulsifying face creams, serums, gels

- Pharmaceuticals: Mixing APIs into suspensions and emulsions

- Food & Beverage: Creating sauces, dairy emulsions, dressings

- Chemicals: Dispersing pigments, waxes, polymers, and surfactants

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

See It In Action

See how Ginhong’s rotor stator mixers simplify your mixing process and enhance emulsion performance:

FAQs

What’s the main advantage of rotor stator mixers?

How small can particles or droplets get?

Are these mixers suitable for continuous production?

Do you offer multi-stage rotor stator designs?

Are rotor stator mixers easy to clean?

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589