High Speed High Shear Mixers

Home >> High Shear Mixers >> High Shear Lab Mixers

High Speed High Shear Mixers

When your application demands both speed and performance, Ginhong’s high speed high shear mixers deliver. Engineered for industries like cosmetics, pharmaceuticals, food, and chemicals, these mixers combine extremely high rotor tip speeds with powerful shear zones to create fine emulsions, dispersions, and suspensions—fast.

Are You Looking for A Reliable Supplier of Mixers?

What is a High Speed High Shear Mixer?

A high speed high shear mixer is an industrial mixing system equipped with a rotor-stator assembly that operates at very high RPMs.

These mixers produce intense mechanical shear and turbulence, allowing rapid breakdown of particles and efficient emulsification.

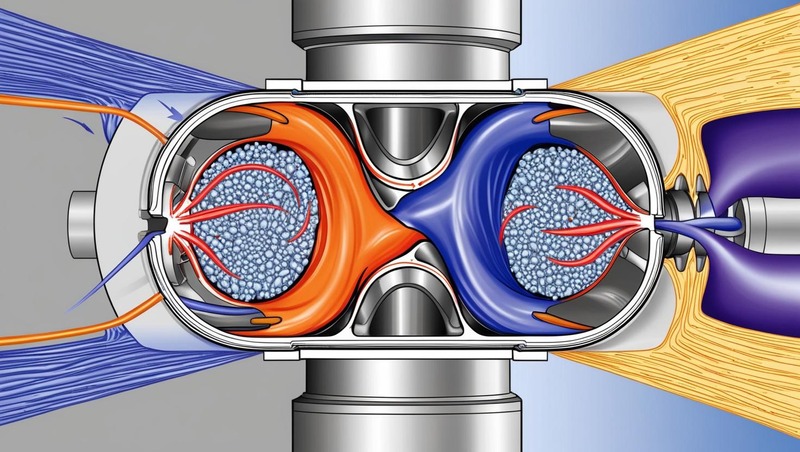

How It Works

As the rotor spins at speeds up to 10,000 RPM or more, materials are drawn into the shear zone and expelled through the stator’s perforations.

The combination of high rotational velocity and narrow gaps creates extreme shear forces that reduce droplet size and blend materials instantly.

Features & Benefits

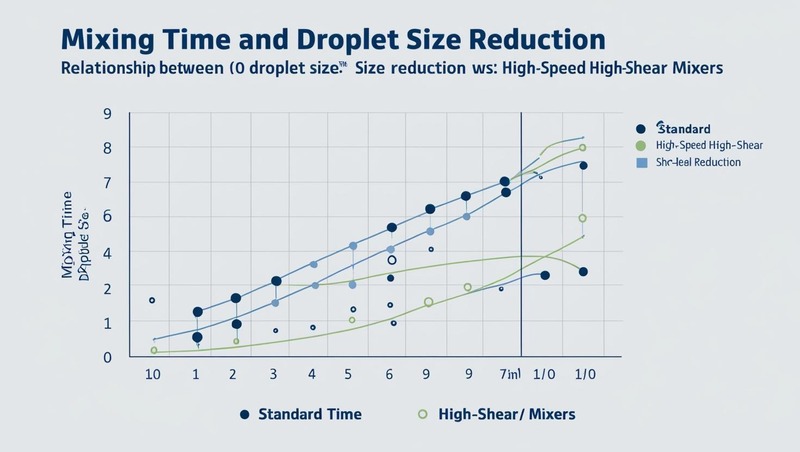

- Fast processing times: Achieve uniform results in minutes

- Fine particle and droplet size reduction

- Variable speed control for process flexibility

- Suitable for high-viscosity and heat-sensitive formulations

- Available in batch or inline configurations

How to Choose the Right High Speed High Shear Mixer

- Viscosity of materials: Ensure the motor and impeller can handle your product’s resistance.

- Target droplet size: Higher speeds are suited for fine emulsions or nano-dispersion.

- Batch or continuous process: Choose batch for flexibility, inline for high-volume throughput.

- Temperature sensitivity: Consider jacketed vessels or vacuum mixing for heat control.

- Product compatibility: Materials should match mixer construction (e.g., stainless steel, Hastelloy).

Our team can help configure a solution based on your formulation and speed requirements.

Typical Applications

- Cosmetics: Emulsifying serums, creams, masks, conditioners

- Pharmaceuticals: Dispersing actives in syrups, suspensions, gels

- Food & Beverage: Blending sauces, emulsions, flavor oils, syrups

- Chemicals: Preparing coatings, adhesives, polymer blends

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

Video: See It In Action

Explore how high shear lab mixers operate and their impact on various mixing processes:

FAQs

What defines a high speed high shear mixer?

Is it suitable for viscous or sticky products?

What are the benefits over standard mixers?

Can it overheat the product?

Are these mixers scalable?

Need speed without sacrificing quality? Contact Ginhong to build a high speed high shear mixing system that keeps your production moving.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589