Using High Shear Mixers for Emulsification

In emulsification processes, achieving uniform droplet size and long-term stability is key—especially in industries like food, cosmetics, pharmaceuticals, and chemicals. At Ginhong, we specialize in high shear mixers that enable efficient and repeatable emulsification results, whether in batch or inline systems.

Are You Looking for A Reliable Supplier of Mixers?

What is Emulsification with a High Shear Mixer?

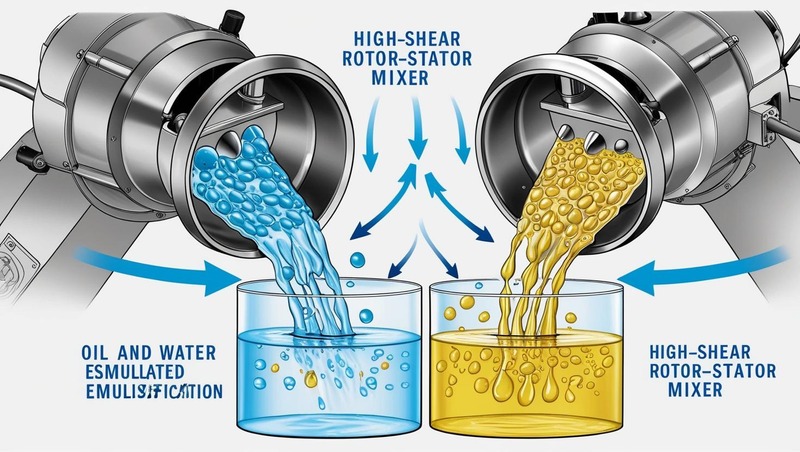

Emulsification is the process of mixing two immiscible liquids (like oil and water) into a stable, homogenous mixture.

High shear mixers use rotor-stator systems to generate intense mechanical shear, reducing droplet size and ensuring a consistent emulsion without phase separation.

How It Works

A high shear mixer rapidly spins a rotor inside a fixed stator, creating a high-velocity shearing field that disperses and emulsifies components.

The intense turbulence breaks up droplets and distributes them evenly throughout the continuous phase.

Features & Benefits

Ginhong’s high shear mixers offer key advantages for emulsification:

- Nano to micro-scale droplet size for highly stable emulsions

- Fast processing times—ideal for time-sensitive formulations

- Improved product consistency with repeatable results

- Handles both low and high viscosity systems

- Available in batch, inline, and vacuum configurations

How to Choose the Right High Shear Mixer for Emulsification

When selecting a mixer for emulsification, consider the following:

- Emulsion type: Are you working with oil-in-water (O/W), water-in-oil (W/O), or multiple emulsions?

- Droplet size requirements: Choose high shear for nano-emulsions or fine microemulsions.

- Viscosity: High viscosity products may require higher torque or multi-stage mixing.

- Batch size and scale: Ginhong offers lab-scale to full-scale production systems.

- Shear intensity: Applications like cosmetic serums or pharma suspensions demand ultra-fine emulsions.

Our engineers can help you match the right shear mixer to your emulsion formulation needs.

Typical Applications

- Cosmetics: Emulsifying face creams, serums, gels

- Pharmaceuticals: Mixing APIs into suspensions and emulsions

- Food & Beverage: Creating sauces, dairy emulsions, dressings

- Chemicals: Dispersing pigments, waxes, polymers, and surfactants

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

See It In Action

See how Ginhong’s rotor stator mixers simplify your mixing process and enhance emulsion performance:

FAQs

What kind of emulsions can I make with a high shear mixer?

What droplet size can a high shear mixer achieve?

Can I use high shear mixers for heat-sensitive emulsions?

What’s the difference between a high shear mixer and a homogenizer?

Do I need a vacuum mixer for emulsification?

Ready to create flawless, shelf-stable emulsions? Contact Ginhong to design your high shear mixing solution today.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589