High Shear and Sanitary Mixers

When cleanliness, compliance, and performance are non-negotiable, Ginhong’s high shear and sanitary mixers are the go-to solution. These mixers are engineered to deliver powerful emulsification, dispersion, and homogenization—while meeting the highest sanitary and regulatory standards in food, pharmaceutical, biotech, and cosmetic industries.

Are You Looking for A Reliable Supplier of Mixers?

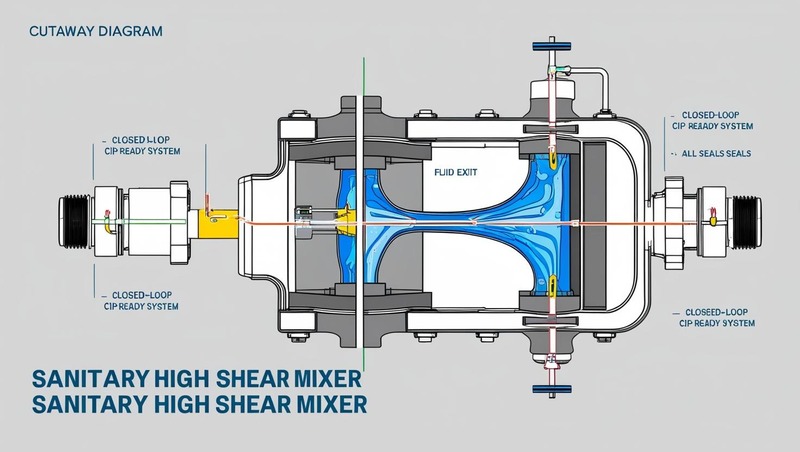

What is a Sanitary High Shear Mixer?

A sanitary high shear mixer is a rotor-stator mixing system designed with hygiene-first features like 316L stainless steel, crevice-free construction, and CIP/SIP compatibility.

It combines intense shear with contamination-free processing.

How It Works

Just like a standard high shear mixer, it uses a high-speed rotor spinning within a fixed stator to create localized shear zones.

In sanitary models, every product contact surface is smooth, corrosion-resistant, and free from bacterial traps. These mixers often integrate into sterile or aseptic production lines.

Features & Benefits

These mixers enable high-performance mixing without compromising on hygiene, making them ideal for sensitive or regulated products.

- 316L stainless steel contact surfaces

- FDA, cGMP, and EHEDG-compliant design

- Clean-in-place (CIP) and steam-in-place (SIP) ready

- Tri-clamp sanitary connections

- Low-maintenance and easy to disassemble (when needed)

How to Choose the Right Sanitary Mixer

- Level of hygiene required: Match equipment design to your regulatory environment (FDA, EU, etc.)

- Viscosity and process type: Ensure compatibility with low or high-viscosity fluids

- Cleaning method: CIP/SIP vs. manual cleanability

- Product sensitivity: Consider air exposure, oxidation, and sterility

- Installation layout: Determine inline or batch setup with proper sanitary fittings

Our team helps ensure your system is both process-efficient and fully compliant.

Typical Applications

- Pharmaceuticals: Sterile suspensions, ophthalmic gels, topical emulsions

- Biotech: Cell culture media, vaccine components, protein dispersions

- Food & Beverage: Sauces, dressings, dairy emulsions, infant formulas

- Cosmetics: Serums, lotions, sunscreens made in sterile environments

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

See It In Action

Watch how sanitary high shear mixers deliver clean, efficient, and consistent results in regulated production environments:

FAQs

What makes a mixer “sanitary”?

Are Ginhong mixers certified for pharmaceutical or food use?

Can sanitary mixers be used in CIP/SIP systems?

Are these mixers suitable for sterile production?

Do you offer mobile or skid-mounted sanitary mixers?

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589