High Shear Pump Inline Mixers

Home >> High Shear Mixers >> High Shear Lab Mixers

High Shear Pump Inline Mixers

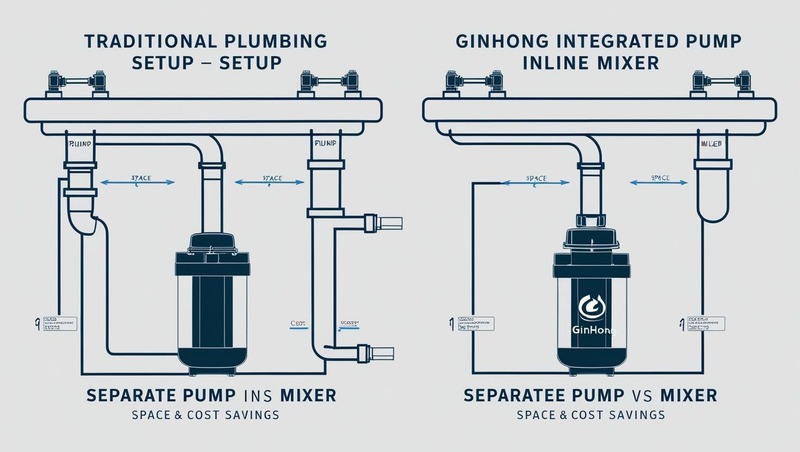

When your production line demands efficient emulsification and fluid transfer in a continuous flow, Ginhong’s high shear pump inline mixers deliver a powerful all-in-one solution. These systems combine high shear mixing with pump functionality—ideal for industries like cosmetics, food, pharma, and chemicals.

Are You Looking for A Reliable Supplier of Mixers?

What is a High Shear Pump Inline Mixer?

A high shear pump inline mixer is a dual-purpose machine that functions as both a high shear mixer and a transfer pump.

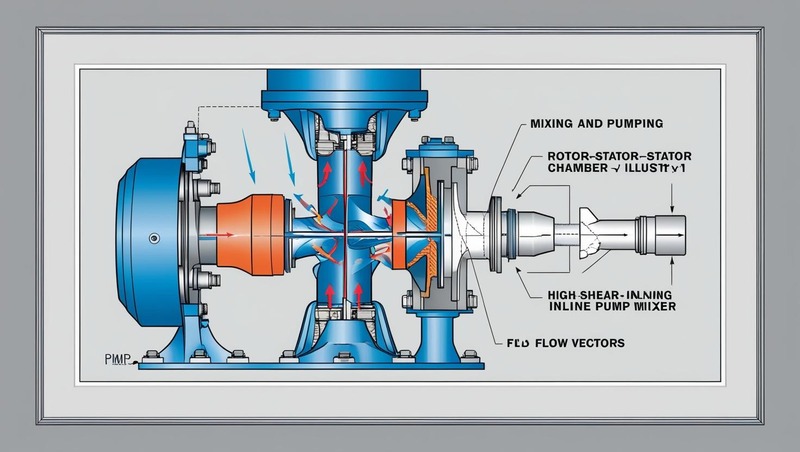

It uses a high-speed rotor-stator mechanism to emulsify or disperse materials while simultaneously transferring the fluid through a pipeline system.

How It Works

As product flows into the mixer chamber, the rotor spins at high speed inside a fixed stator, creating zones of intense shear.

This not only mixes and breaks down droplets or particles but also propels the fluid forward, eliminating the need for a separate pump.

Features & Benefits

- Two-in-one design reduces footprint and equipment cost

- Continuous inline processing for consistent product quality

- Handles low to high viscosities with powerful rotor dynamics

- CIP/SIP compatible for hygienic applications

- Variable speed control for adjusting shear intensity and flow rate

How to Choose the Right High Shear Pump Mixer

- Flow rate requirements: Match the mixer’s pumping capacity to your line’s throughput.

- Viscosity range: Choose models designed to handle your product’s flow resistance.

- Process type: Determine whether the system will be used for emulsification, dispersion, or general mixing.

- Material compatibility: Ensure the pump head materials suit your product (e.g., 316L SS, Hastelloy).

- Integration flexibility: Consider layout, control systems, and sanitary requirements.

Our engineers can recommend the best configuration based on your plant layout and process needs.

Typical Applications

- Cosmetics: Transferring and emulsifying lotions, gels, conditioners

- Food & Beverage: Continuous mixing of dressings, sauces, dairy emulsions

- Pharmaceuticals: Preparing suspensions, ointments, and syrups inline

- Chemicals: Mixing and circulating resins, lubricants, cleaners

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

See It In Action

See how high shear pump inline mixers streamline production and reduce equipment needs:

FAQs

What makes a high shear pump mixer different from a standard inline mixer?

Can it handle thick, viscous materials?

Is this system CIP compatible?

Can I replace both my inline mixer and pump with this unit?

What industries benefit most from pump inline mixers?

Simplify your line, enhance mixing power, and cut equipment costs—talk to Ginhong about our high shear pump inline mixer solutions today.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589