High Shear Mixers and Homogenisers

In many industries—especially food, cosmetics, pharmaceuticals, and chemicals—the terms high shear mixer and homogeniser are often used interchangeably. But while they share some overlap, these machines serve different purposes and excel in different stages of the mixing process. At Ginhong, we provide both technologies to help you create efficient, stable, and scalable formulations.

Are You Looking for A Reliable Supplier of Mixers?

What’s the Difference Between High Shear Mixers and Homogenisers?

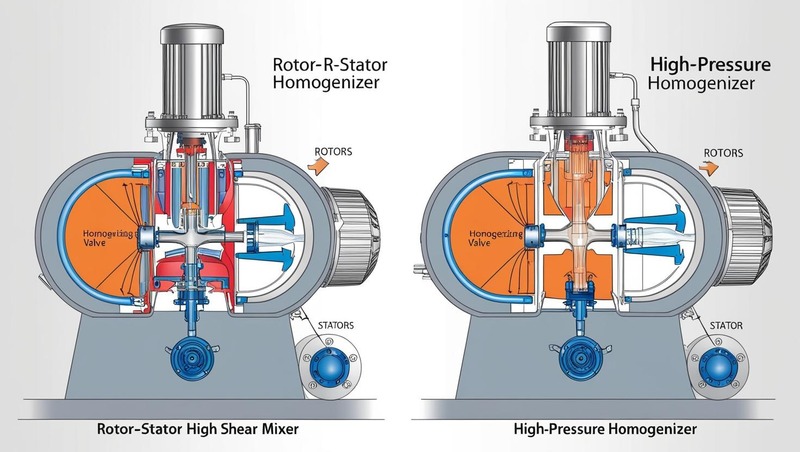

A high shear mixer uses a mechanical rotor-stator system to generate intense localized shear, dispersing and emulsifying materials. A homogeniser, often high-pressure based, forces fluid through a narrow gap or valve, producing extreme pressure drops and turbulence to further reduce particle and droplet sizes.

How Each One Works

High Shear Mixer:

- Rotor spins inside a stator at high speed

- Generates shear fields for emulsification and dispersion

- Ideal for primary mixing and pre-emulsification

Homogeniser:

- Applies pressure (up to 20,000 psi) to push product through a homogenising valve

- Breaks down particles into ultra-fine sizes

- Used for final-stage homogenisation and particle size refinement

Features & Benefits Comparison

| Feature | High Shear Mixer | Homogeniser |

|---|---|---|

| Shear Type | Mechanical (rotor-stator) | Hydraulic (pressure drop) |

| Particle Size | 1–5 μm | Submicron (0.1–1 μm) |

| Use Stage | Pre-mix, batch, continuous | Final finishing, continuous |

| Viscosity Range | Wide range | Low to medium |

| Maintenance | Low | Medium to high |

When to Use a High Shear Mixer vs. a Homogeniser

Use a high shear mixer if:

- You need to mix or pre-emulsify viscous ingredients

- You’re processing in batches or inline with mid-size particles

- You want lower energy consumption and easier maintenance

Use a homogeniser if:

- You need ultra-fine emulsions or submicron dispersions

- You’re processing low-viscosity liquids continuously

- You’re manufacturing high-end cosmetic or pharmaceutical products

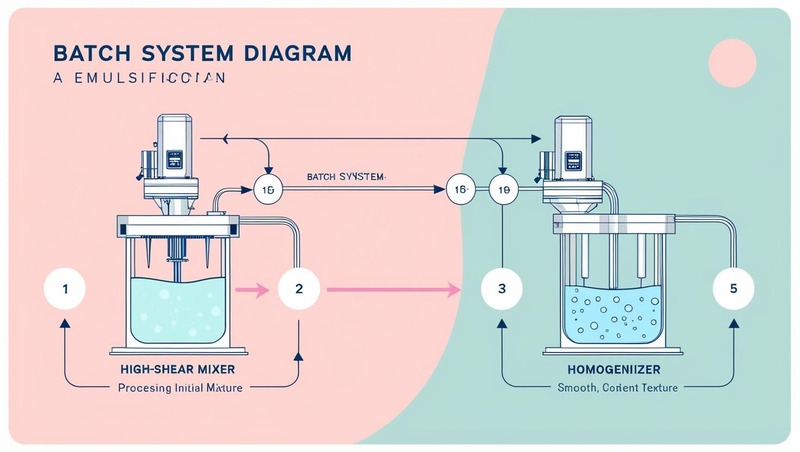

Integrated Systems: Best of Both

At Ginhong, we offer integrated mixing systems that combine the strengths of both technologies:

- Pre-emulsification with a high shear batch or inline mixer

- Finishing with a high-pressure homogeniser

- Fully automated control systems

This approach maximizes processing efficiency and product stability across a wide range of formulations.

Typical Applications

- Cosmetics: Lotion and serum production with glossy, stable finish

- Pharmaceuticals: Suspensions and injectable emulsions

- Food & Beverage: Creamy sauces, flavored dairy drinks

- Chemical: Lubricants, coatings, cleaning agents

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

See It In Action

See how Ginhong’s rotor stator mixers simplify your mixing process and enhance emulsion performance:

FAQs

What’s the key advantage of using both a high shear mixer and homogeniser?

Can a high shear mixer replace a homogeniser?

Are homogenisers suitable for high-viscosity materials?

How does maintenance compare?

Can Ginhong supply both types of equipment?

Ready to find the best mixing and homogenising solution for your process? Contact Ginhong today and let’s build the ideal system for your product.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589