Pharma High Shear Mixers

In pharmaceutical manufacturing, consistency, safety, and cleanliness are paramount. Ginhong’s pharma high shear mixers are specifically engineered to meet the stringent requirements of cGMP environments, delivering high-efficiency mixing, emulsification, and granulation for a wide range of drug formulations.

Are You Looking for A Reliable Supplier of Mixers?

What is a Pharma High Shear Mixer?

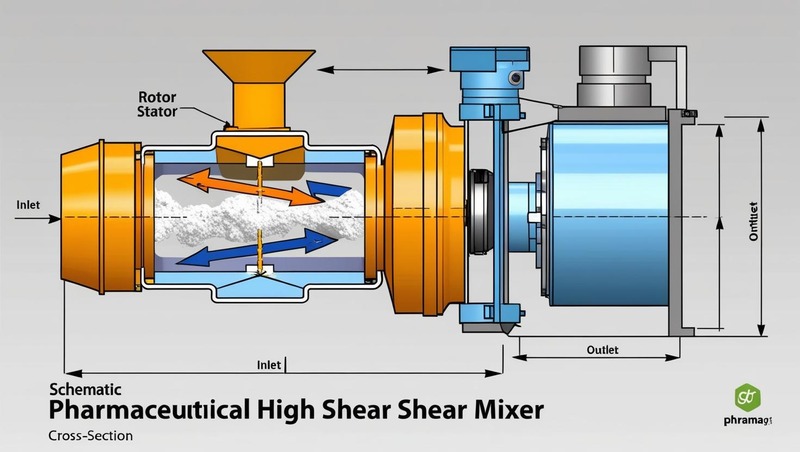

A pharma high shear mixer is a sanitary-grade industrial mixing system that uses a high-speed rotor-stator mechanism to produce uniform emulsions, dispersions, or wet granulations.

It’s designed for pharmaceutical applications where particle size, stability, and repeatability are critical.

How It Works

The rotor rapidly spins within a stator, creating intense mechanical shear and turbulence.

This action breaks down particles and disperses active pharmaceutical ingredients (APIs), excipients, or binders evenly throughout the mixture.

Features & Benefits

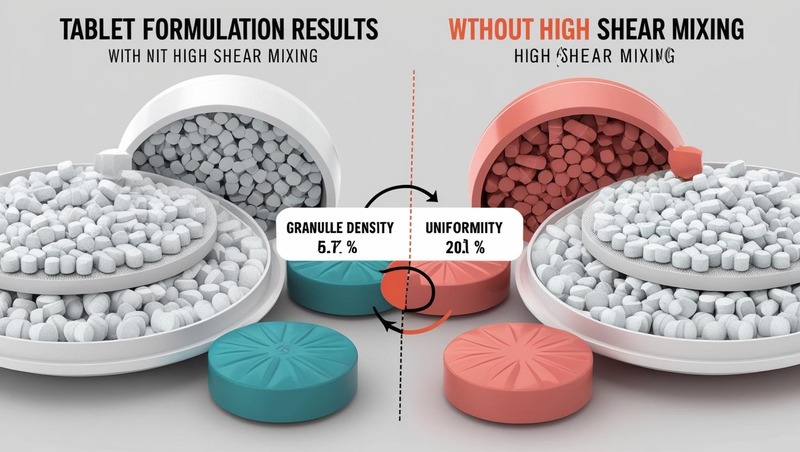

Pharma high shear mixers ensure formulation consistency, reduce processing time, and improve downstream performance in tablets, capsules, and suspensions.

- Compliant with cGMP and FDA standards

- Sanitary design with 316L stainless steel contact parts

- Fully drainable and CIP/SIP ready for sterile processing

- Uniform wet granulation and fine emulsification of APIs

- Integrated controls for precise mixing parameters and batch repeatability

How to Choose the Right Pharma Mixer

- Formulation Type: Are you producing suspensions, creams, ointments, or granules?

- Scale: Choose lab-scale mixers for R&D and larger inline mixers for commercial production.

- Shear Intensity: Sensitive APIs may require adjustable speed and shear control.

- Cleaning Requirements: Ensure your system is CIP/SIP compatible and easily sterilizable.

- Validation: Equipment should include data logging and automation features to meet validation protocols.

Our experts can help match the optimal Ginhong mixer to your pharmaceutical workflow.

Typical Applications

- Oral suspensions: Uniform distribution of APIs in syrups and liquids

- Topical creams and gels: Smooth, stable textures for transdermal delivery

- Wet granulation: Binder dispersion for compactable tablet granules

- Ointments and pastes: Uniform mixtures with enhanced bioavailability

- Injectable emulsions: Pre-emulsification before sterile filtration

Industries Served

Ginhong's mixers are widely used to make cream, ointment, lotion, and emulsion in cosmetic, pharmaceutical, food and chemical industries.

Equipment for Making Cosmetics

Pharmaceutical Processing

Chemical Processing Equipment

Food Processing Mixers

Video: See It In Action

Watch how used and refurbished mixers can still perform at high levels:

FAQs

What certifications do Ginhong’s pharma mixers comply with?

Can I use high shear mixers for both emulsification and granulation?

Are Ginhong mixers suitable for aseptic environments?

How do I scale up from lab to production?

Can pharma mixers handle high-viscosity materials?

Looking for a pharma-grade mixer you can trust? Contact Ginhong to customize a high shear solution for your pharmaceutical process.

WRITE TO US

Request A Free Quote

Have Any Questions?

- +86-517-8689 5589

- info@ginhong.com

- +86 18951262589